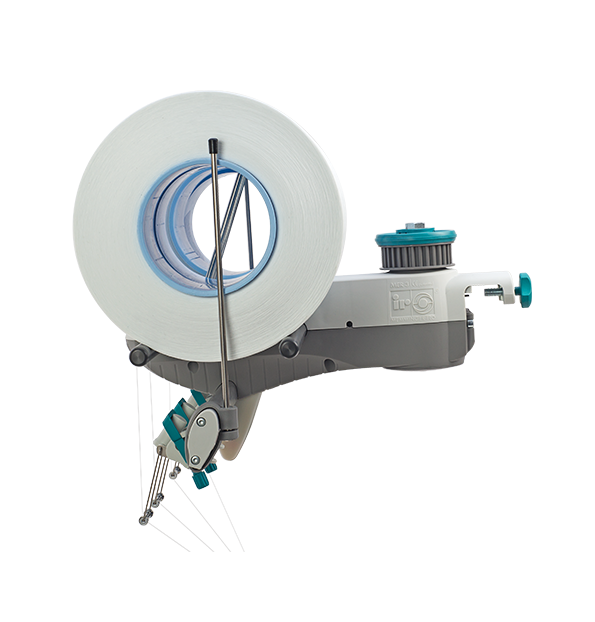

MER 3 - Elastane roller

Application

This universal elastane roller is designed for the positive feeding of plain elastane yarn to large-diameter circular knitting machines. The MER 3 makes it possible to process plain elastane at even lower yarn tensions.

Main features

- The stop motion system has been completely redesigned for minimum yarn tensions

- The automatic adaptive electronic stop motion system is integrated in the stop motion electric circuit

- Highly versatile thanks to universal single ratio

MER 3: The components

Shutdown system:

The shutdown system operates using the force of gravity. If the yarn breaks, contactless magnetic force trips the shutdown system.

Colour-change warning light:

The warning light is mounted in a central, highly visible position. Yarn breakages are indicated by a colour change.

Cover (optional):

This protects the elastane bobbins from lint thereby reducing machine stoppages and knitting faults caused by contamination. It increases machine productivity.

1. Shutdown system

The shutdown system operates using the force of gravity. If the yarn breaks, contactless magnetic force trips the shutdown system.

2. Colour-change warning light

The warning light is mounted in a central, highly visible position. Yarn breakages are indicated by a colour change.

3. Cover (optional)

This protects the elastane bobbins from lint thereby reducing machine stoppages and knitting faults caused by contamination. It increases machine productivity.

Technische DatenTechnical data

Stop motion electric circuit with yarn break Rated voltage (machine stoppage) | 12/24 V AC/DC |

|---|---|

Max. current consumption with stop motion | 25 mA |

Yarn tension | min. 0.8 cN |

VariantenVersions

ZubehörAccessories

Cover

This protects the elastane bobbins from lint, so reducing machine stoppages and knitting faults caused by contamination. Significantly increases machine productivity.

MER 3 stop motion system

The stop motion system operates using the force of gravity. If the yarn breaks, the stop motion system is tripped by contactless magnetic force.

Contact cable

2-core contact cable for electrical connection of MER 3.

DownloadsDownloads

-

- Spare parts lists

- MER 3 (620 KB), German

- MER 3 (620 KB), English

-

- Operating instructions

- Operating Instruction (2 MB), German

- Operating Instruction (2 MB), English

- Operating Instruction (2 MB), Spanish

- Operating Instruction (2 MB), French

- Operating Instruction (2 MB), Italian

- Operating Instruction (2 MB), Turkish

- Operating Instruction (2 MB), Portuguese

- Operating Instruction (2 MB), Chinese-trad.

- Operating Instruction (2 MB), Polish

-

- Installation instructions

- Cover (326 KB), Ger.-Engl.

-

- Information material

- Questionnaire (229 KB), German

- MER 2/MER 3 Comparison of the Products (303 KB), German

- Questionnaire (221 KB), English

- MER 2/MER 3 Comparison of the Products (303 KB), English

- Attaching Parts for Elastane (140 KB), Ger.-Engl.

- Covers (137 KB), Ger.-Engl.

- Rotate twin pulley for MER 3 (146 KB), Ger.-Engl.

- Contact Cable (99 KB), Ger.-Engl.

- MER 3 Productmodification Sensor (389 KB), Ger.-Engl.

- MER 3 Product Modification Drive shaft (80 KB), Ger.-Engl.

-

- Electrical connection

- Stop relay box (72 KB), German